by Hans D. Stroo on July 22, 2016

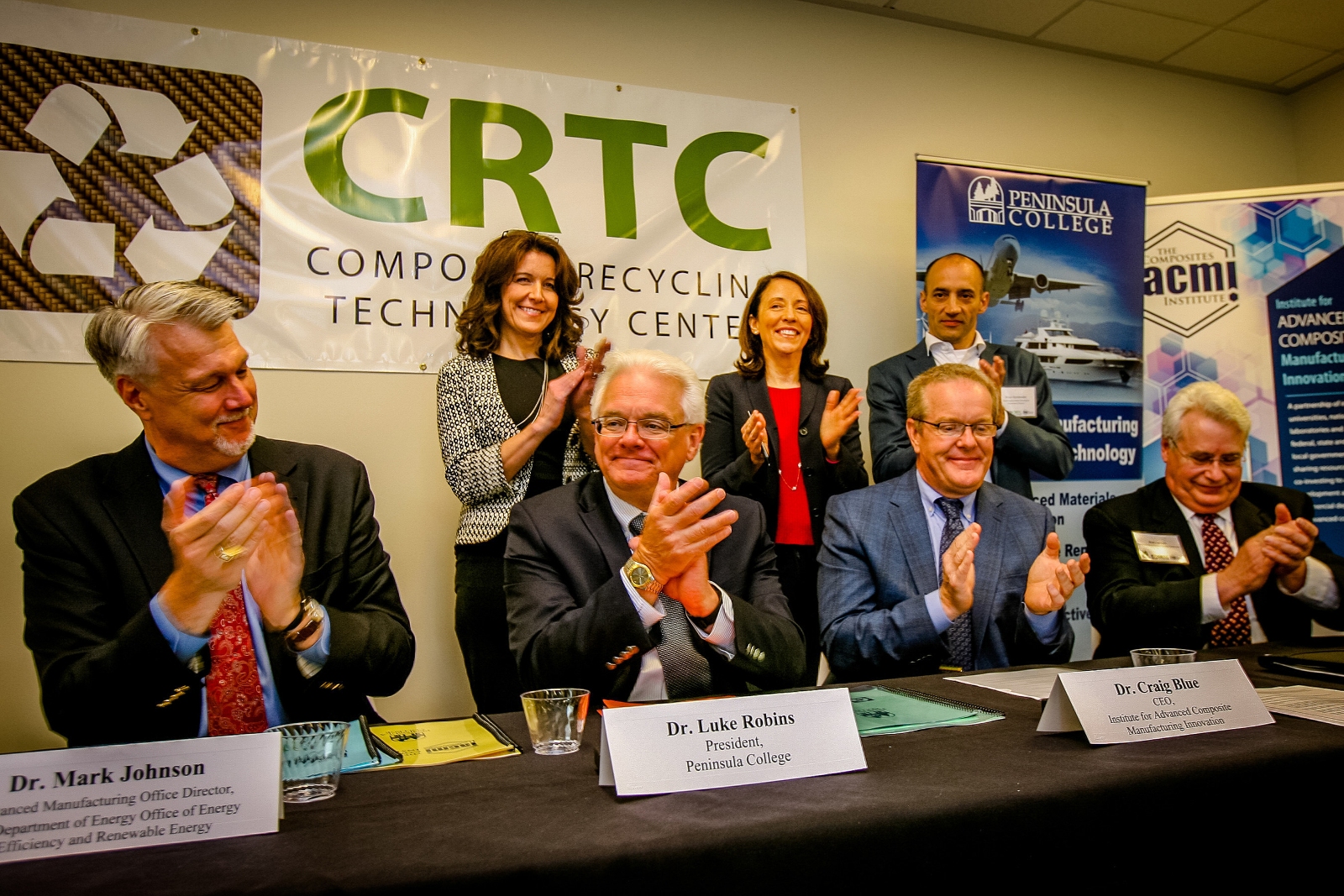

Port Angeles, WA — Earlier this month a new agreement was announced between the Composite Recycling Technology Center (CRTC), the Tennessee-based national composites manufacturing institute, and Peninsula College. Washington’s junior U.S. Senator Maria Cantwell presided over the signing of collaboration agreements that established the CRTC as a strategic partner and West Coast satellite location for the Institute for Advanced Composites Manufacturing Innovation (IACMI), and allows Peninsula College to expand their capacity for training the composites manufacturing workforce of the future.

The CRTC is a prime model that aligns with PLAN Washington’s strategies to support economic growth in rural communities and innovative environmental solutions. Composite recycling supports workforce development in Washington State and the growth of the advanced manufacturing industry. Two million pounds of carbon fiber composite material are landfilled in Washington annually. Reducing waste, especially the waste of energy-intensive composite materials, increases the carbon competitiveness of Washington State’s economy— a key goal of PLAN Washington.

CRTC CEO Robert Larsen opened the event by underlining the novelty of Port Angeles’s own CRTC. “The CRTC is unique in the world for its focus on making new end-use products directly from scrap,” he said. The CRTC is an independent not-for-profit corporation originally created by the Port of Port Angeles. The Center was created in order to launch a world-leading industry for reclaiming, recycling, and reprocessing carbon fiber composites. Diverting this waste stream into productive applications can accelerate Washington’s advanced manufacturing industries, attract foreign and federal investment, and create new opportunities for highly-skilled workers.

CRTC CEO Robert Larsen opened the event by underlining the novelty of Port Angeles’s own CRTC. “The CRTC is unique in the world for its focus on making new end-use products directly from scrap,” he said. The CRTC is an independent not-for-profit corporation originally created by the Port of Port Angeles. The Center was created in order to launch a world-leading industry for reclaiming, recycling, and reprocessing carbon fiber composites. Diverting this waste stream into productive applications can accelerate Washington’s advanced manufacturing industries, attract foreign and federal investment, and create new opportunities for highly-skilled workers.

“Port of Port Angeles is taking the lead for the nation in solving carbon fiber recycling for manufacturing,” said U.S. Senator Cantwell. “This agreement gives the Composite Recycling Technology Center real world-class chops in solving how to break-down carbon fiber which will lead to jobs.”

Carbon fiber composites are revolutionizing aerospace, automotives, maritime, and many other industry. Carbon fiber is stronger than steel and lighter than aluminum, and yet over 29 million pounds of composite scrap end up in US landfills every year – a challenge the new partnership will meet head on. The CRTC will serve as the West Coast “portal” for the IACMI with access to world-class facilities, equipment, and partners.

Larsen opened the ceremony with a brief primer on carbon fiber. It “is woven from thousands of resin-coated pure carbon filaments,” he explained. “Before it gets transformed into a part or product, carbon fiber looks like a thin black fabric wound into rolls that are kept refrigerated to retard self-curing and maintain flexibility. After the product is cut out of the fabric and molded into shape, it’s cured at high temperature and pressure to transform it into a hard, stiff, and stable material.” The CRTC is the world’s first facility to divert uncured carbon fiber scrap from the landfill into innovative new products.

Larsen opened the ceremony with a brief primer on carbon fiber. It “is woven from thousands of resin-coated pure carbon filaments,” he explained. “Before it gets transformed into a part or product, carbon fiber looks like a thin black fabric wound into rolls that are kept refrigerated to retard self-curing and maintain flexibility. After the product is cut out of the fabric and molded into shape, it’s cured at high temperature and pressure to transform it into a hard, stiff, and stable material.” The CRTC is the world’s first facility to divert uncured carbon fiber scrap from the landfill into innovative new products.

Colleen McAleer spoke at the event. She is a Commissioner at the Port of Port Angeles who spearheaded creation of the CRTC in her previous post as the Port’s Director of Business Development. “The principal role of any Port in this state is to expand the local economy by employing Port resources,” McAleer said. “The CRTC is the first of its kind. Before this, a port had never used its powers to start and operationally fund a nonprofit (through an economic development services contract) in order to jumpstart a local economy. The CRTC will convert a displaced workforce and unused facilities into an innovative market to create local jobs, reduce landfill waste and save energy by recycling valuable scrap carbon fiber.” The CRTC’s bold mission involves filling an unmet market demand within a high tech niche market in order to create a nascent industry sector with all the associated upside economic opportunities.

An economic impact study predicts the CRTC will create approximately 338 new jobs in Clallam County with an average annual wage of $67,553.

McAleer, one of the CRTC’s earliest and most active champions, pointed out how many supporters it took to get the project launched and operational. She acknowledged the many people who deserved credit. “Senator Cantwell early on recognized this innovative and bold approach of Port assets and has been a staunch advocate for the CRTC ever since,” McAleer said. “Much of the success we celebrate today must be credited to her, our Governor, our County Commissioners and the many staff members at the Port and the CRTC that have diligently worked to make the vision become a reality for Clallam County.”

ABOUT THE COMPOSITE RECYCLING TECHNOLOGY CENTER (CRTC)

The CRTC is an innovative non-profit company founded in 2015 whose mission is to lead and grow a composite recycling industry that diverts carbon fiber scrap that is destined for landfill, and turns it into value-added products. The CRTC will accomplish its mission through direct product manufacturing, by providing technical design services, and by making low-cost recycled carbon fiber feedstock available for other manufacturers to utilize. The CRTC is supported by a $1.9M commitment from the Port of Port Angeles, with infrastructure investment from partners at the US Department of Commerce-Economic Development Administration, WA State’s Clean Energy Fund, Clallam County, and City of Port Angeles. Find out more at compositerecycling.org

ABOUT PENINSULA COLLEGE

Peninsula College provides educational opportunities in the areas of academic transfer, professional and technical, basic skills, and continuing education. Their Advanced Manufacturing – Composites Technology Program prepares students for the wide-ranging field of composite structure fabrication and repair. Through classroom work and hands-on training, the program equips students with skills necessary for employment in the aerospace, marine, and recreational equipment industries, as well as many others that use composite materials. More information on their Advanced Manufacturing – Composites Technology Program can be found at: pencol.edu/proftech/composites-technology

ABOUT THE NATIONAL COMPOSITES INSTITUTE (IACMI)

The Institute for Advanced Composites Manufacturing Innovation (IACMI), managed by the Collaborative Composite Solutions Corporation (CCS), is a partnership of industry, universities, national laboratories, and federal, state and local governments working together to benefit the nation’s energy and economic security by sharing existing resources and co-investing to accelerate development and commercial deployment of advanced composites. CCS is a not-for-profit organization established by The University of Tennessee Research Foundation. The national institute is supported by a $70 million commitment from the U.S. Department of Energy’s Advanced Manufacturing Office and over $180 million committed from IACMI’s partners. Find out more at IACMI.org