Cobalt Enterprises, the award-winning Granite Falls aerospace parts manufacturing plant on the Mountain Loop, participated with Granite Falls High School teacher Michael Werner’s manufacturing class in providing a first-hand opportunity for students to see the functions of the plant.

Not to be mistaken for “just another pretty face”, tour director Hailey Francis’ high energy and impressive knowledge helped her easily connect with GFHS students during the November 20 event. At 24, Francis’ high school experiences are still fresh in her memory, as are her recollections of worrying about “what she wanted to be when she grew up”. Francis graduated from Lake Stevens High School in 2010 without a clear idea on what her future held.

Not to be mistaken for “just another pretty face”, tour director Hailey Francis’ high energy and impressive knowledge helped her easily connect with GFHS students during the November 20 event. At 24, Francis’ high school experiences are still fresh in her memory, as are her recollections of worrying about “what she wanted to be when she grew up”. Francis graduated from Lake Stevens High School in 2010 without a clear idea on what her future held.

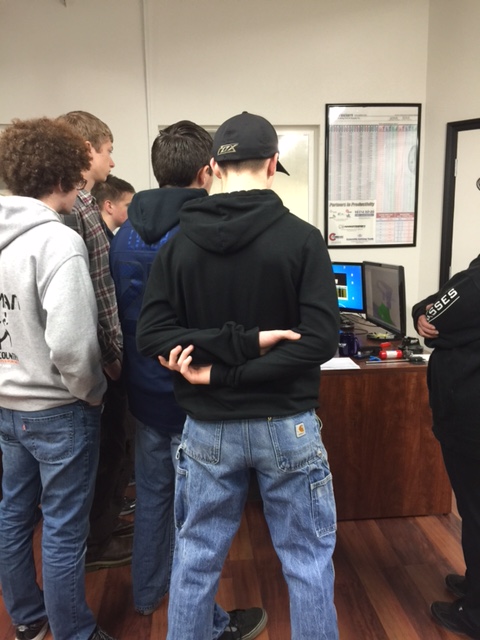

About a dozen students took part in the morning tour, most of whom were in Werner’s first year manufacturing class with a few in advanced.

A focus of the tour was to expose students to job opportunities and careers in which they might find their niche, perhaps in part using what they’re learning in Werner’s classes. Cobalt Vice President Paul Clark explained that there are many opportunities for a variety of skilled workers, both those who have acquired relevant technical education and those who might learn through on-the-job training. When asked what skills were required to be hired at Cobalt, Clark said, “Manufacturing calls for creativity, problem solving, teamwork and a healthy level of math and science. There are hundreds of companies with opportunities for young workers.”

Their interest was obvious as they visited the various departments including programming and design, tooling, manufacturing, deburring, finishing and labeling. They were impressed with the precision and strict variances required in tooling and producing the end products, oftentimes with tolerances less than that of a human hair.

The morning came to an end too soon, but it was clear an impression had been made on these kids, hopefully one that would help direct their tomorrows.

Werner has worked with students from the Granite Falls High School as part of Career and Technical Education 21st Century updates at Granite Falls High School. He was hired to create a world class manufacturing program. He helped design the new High School facility (built in 2008) and purchase state-of-the-art CNC machines. High-end computer technology was combined with the traditional manual equipment. His goal was to create a program based on real world projects that would allow students to apply high level academics in “research, design and build” team projects, blended with hands-on “Old World” skills, as they prepared for STEM careers through manufacturing.

One such student was Aron Scalf who graduated from Granite Falls High School in 2011. Catching up with him on his memories of Werner’s classes he recalls that time with apparent fondness, saying, “I remember the first project he always had his students do was seemingly simple — to design and create a new kitchen utensil using hand tools and a pen and paper. Many students struggled at first,” he continued, “unable to think of something new, how to make it, etc. What they were learning was something I learned very quickly — there’s much more to manufacturing than the often heard, ‘I want to make this.’ Right away you could tell some students were very discouraged, thinking hand tools were outdated and useless. They just wanted an easy “A” class.”

Students watch as computer programmer Gary Gaines demonstrates his CAD programming

“Fast forward a little bit,” he said, “and everyone had passed all the safety quizzes to use power tools. They quickly deferred back to ‘I want to make this’ and Mr. Werner brought them back to the how, with what, what does it do, etc.”

“Then came CNC ( computer numerical controlled ) machines, the most advanced type of tool used in the industry. Very few people made it there due to the short school year, but the ones who did had learned the whole of the manufacturing process, now utilizing the most advanced tool for their ideas,” shared Scalf.

So where did it take him from there? “Outside of this class was the eco-car program,” he said. “This was a real-life, true test of manufacturing, not just something for a grade in school, but for a real world fuel economy application. It was designed on paper, modeled by hand, created with power tools, and finished with CNC machines. The very evolution of manufacturing happened right there in that shop.”

When asked to share how he’s used this in his today’s life, Scalf said, “Well now, let’s relate this all to my current job. I build airplanes, plane (haha) and simple on the outside. But get down to it and is so much more than that. We’ve only designed and a created a new version of something that already exists — like the kitchen utensil. We had to think of something new and how to make it,” he said, obviously reflecting back on days in class.

“So out came the thought of becoming more fuel efficient, for various reasons. The first step in the process of manufacturing anything is the idea. Next was pencil and paper, design the thought. Then came the model. Next thing we know, this thought had become reality. We had a whole lot of nothing to make something out of. So out came the tools. Hand tools mostly, even as advanced as an airplane (or anything for that matter) is there will always be a need for hand tools. Next thing I know the same hand tools I used to create my first project were in my hands again to create the first airplane anywhere of its kind. Power tools came next, as they did in the shop, many of the same ones in fact. They opened up new ideas, and just like high school, brought us back to the drawing board of how it works and why/why not, etc. Bring it to present day and CNC machines are getting involved in the process helping us manufacture planes that just a little while before were merely an idea.”

“To me,” Scalf said in concluding, “The class wasn’t a class at all; it was a constant lesson, a life lesson even. Manufacturing to me, in its essence, is creating something from seemingly nothing. Something we all do everyday — your input becomes life’s output. The students in that class are learning not only how to manufacture something from an idea, but how to use it in ways that are more than applicable to the rest of their lives.”

An impressive “tool box”